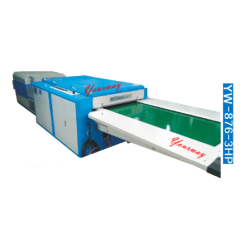

| 型號 Model | YW-876-3HP |

| 機器尺寸 Machine Size | 591*155*106CM |

| 電壓 Power Voltage | 380V/ 50HZ |

| 功率 Input Power | 13KW |

| 貼合寬度 Laminating Width | 600MM |

| 馬力 Motor | 1/2HP |

| 淨重 Net Weight | Approx. 685KG |

特性/ Features:

1.此機台加裝了電腦控制面板以利操作人員根據.不同的材來進而有更精確的設定。

This new model of YW-876-3HP is designed with PLC and computer controlling screen in order to help operator set up detailed setting based on different materials.

2.六段式加長熱壓。

For YW-876-3HP processes the input materials by 6 phase to avoid input over-heated, because of this, the result proves that this machine produces great quality of outputs.

3. 高效冷凍。

One of the six stages of this machine is the high efficiency chilling (cold) stage. It cools down the hot surface of the products and high temperature materials. It also keeps the final shape of the products away from getting overheated.

4. 自動調節壓力。

YW-876-3HP adjusts the pressure based on different materials automatically.

5. 適合多種材料貼合或發泡印刷鞋面。

This machine attaches and forms one material with other materials.

6. 此機採用開邊式, 適合較大裁片及鞋面內襯補強片貼合。

YW-876-3HP is designed open-sided. Thus, it works great on large pieces laminating and shoes vamp lining laminating.

7.採用無接縫鐵氟龍運輸帶. 採用有特殊構造裝置, 可自動排除皮帶偏離, 確保皮帶使用壽命更長。

Our company uses No-Sew Teflon Conveying Belt as the material. The structure of this machine is specially designed to help avoiding the conveying belt to go off the track and the extending using lifetime for conveying belt.

8. 上下層運輸帶裝有清潔刮片, 能及時清理雜物, 使貼合效果更佳。

Both of the upper and lower conveying belts have cleaning blades to clean up/ move away the dirt. With the cleaning blades, products get laminated better.

9. 加熱方面採用前後分開控制溫控, 同時採用了固態繼電器, 使溫度更準確。

YW-876-3HP has two temperature controllers, which are the front temperature controller and back temperature controller. Besides these two temperature controllers, SSR is also installed in both of these machines. With all of these, the temperature can be control and measure accurately.

10. 加工寬度為600mm, 輸送長度為2000mm, 加熱空間為1000mm, 以2000mm*100mm材料計算每分鐘可壓150片材料, 根據不同材料, 可調快慢。

The width range of product to be processed is up to 460mm and the conveying length is 2000mm. The size of the heating area is 1000mm. A material of 2000mm*100mm can be separated into 150 pieces every minute. The working speed can be change based on the different materials.

11. 壓力方面採用氣壓式加壓, 根據不同材料可調氣壓閥來控制壓力大小。

This machine uses pneumatic to give pressure to for hot pressing. Pneumatic valve is able to control the pressure base on different materials.

12. 作業使用連續式無接縫鐵龍輸送帶, 不僅能提高黏合效果更能提高生產效率

With no-Sew Teflon Conveying Belt, it helps increasing productivity and laminating.

13. 溫度設置前, 中, 後以及上,下層採用獨立溫控偵測溫度, 同時採用電子調溫器及固態繼電器(SSR)使溫度偵測更準確

YW-876-3HP is designed with six temperature controllers, which are front, middle, back, upper and lower temperature controllers. Moreover, with the SSR system, operator can measure the temperature accurately.

14. 根據不同材料, 本機裝有冷卻系統, 可在貼合後即時冷卻, 確保貼合材料在短時間內冷卻定型, 發揮更加的貼合效果

This machine is designed with Cooling System, the system makes sure that all the materials cool down and shaped after laminating within a short period of time.